#bitcoin #ICO #bitchain #btc #cryptocurrency #money #market #crypto #investing #today #trading #value #cash #getbitcoin #bitcointops #currency #dollar #crash #million #coinbase

#investing #today #trading #value #cash #getbitcoin #bitcointops #currency #dollar #crash #million #coinbase #bitcoin #ICO #bitchain #btc #cryptocurrency #crypto

#goBack #lost #hello #back #helloWorld #bitcoin #loosed #find #post #nono #why #yes #bitcoin #getbitcoin #search #currency #dollar #IamLost #findMe #searchMe

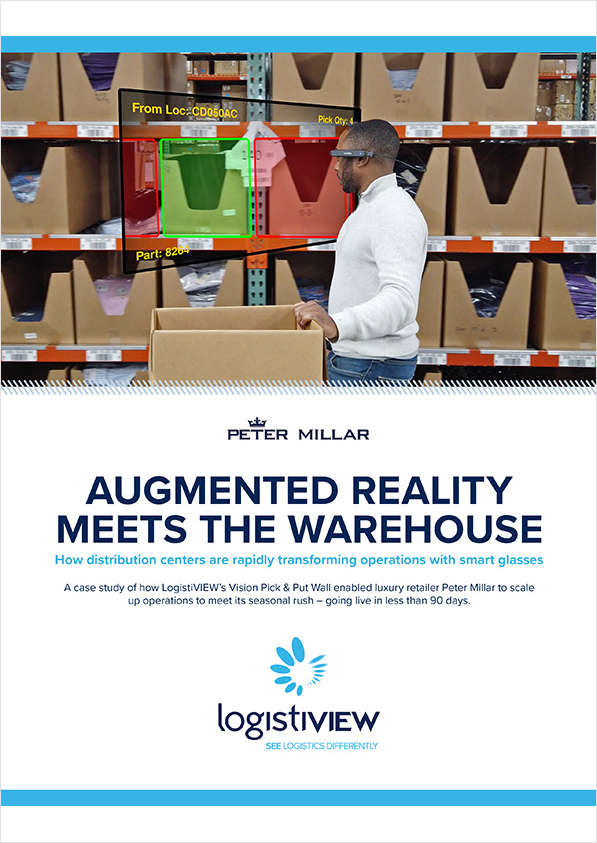

Peter Millar, luxury apparel retailer, took a different approach to automating their omni-channel warehouse. They found a way to streamline orders, take 10% load off of their conveyor, dramatically reduce touchpoints, and adapt whenever the business calls for a change. How did they do it? Flexible Automation with LogistiVIEW. Harnessing Augmented Reality smart glasses to reinvent order operations.

The need:

A new picking and sorting process to reduce strain on the conveyor, increase picking speed and accuracy, and reduce audit/pack out labor

The Challenge:

Over Capacity DC: As an omni-channel fulfillment center, Peter Millar’s DC was designed for a peak season e-commerce surge, but no one predicted the incredible growth in sales that Peter Millar achieved in just a few short years.

Picking Inefficiency at Peak and Redundant Touchpoints: Normal operations focused on large retail orders, with e-commerce orders mixed in that actually improved pick density. But at Peak, the opposite occurred, increasing walk times for single picks that would be better batch-picked and post sorted.

Conveyor Congestion: Peak also meant a huge spike in the number of separate outbound boxes – overloading the conveyor, and gridlocking the packing and sorting process.

Cost of Accuracy: As a rule, a congested conveyer leads to product jumping to adjacent cartons, increased pick touchpoints naturally proliferate pick errors, and recirculation leads to audit/packing inefficiency for retail orders.